Reduce Returns With TVA

Auditing product pages for accuracy reduces returns.

Some returns are inevitable, but many can be prevented with TVA

A good starting point for reducing return rates is to understand why products are being returned and how to prevent these issues in the future. It's straightforward!

Some common, avoidable reasons for returns include:

- Incorrect Fit or Compatibility: Sometimes, the part ordered may not fit the vehicle due to incorrect model, make, or year information, even though it appears compatible online.

- Part Looks Different: Issues arise when the received product looks different from what was shown on the website.

- Incorrect Materials or Attributes: Problems occur if the material or attributes of a part are misrepresented, such as advertising a part as steel when it is actually aluminum.

Quick Version

To reduce auto part returns, use True View Audits (TVA) to improve page accuracy by addressing common issues:

- Incorrect Fit or Compatibility: Ensure fitment data is accurate by auditing against ACES® standards.

- Part Looks Different: Compare product images with the latest PIES® data to avoid mismatches.

- Incorrect Materials or Attributes: Verify product details against ACES® and PIES® data to prevent errors.

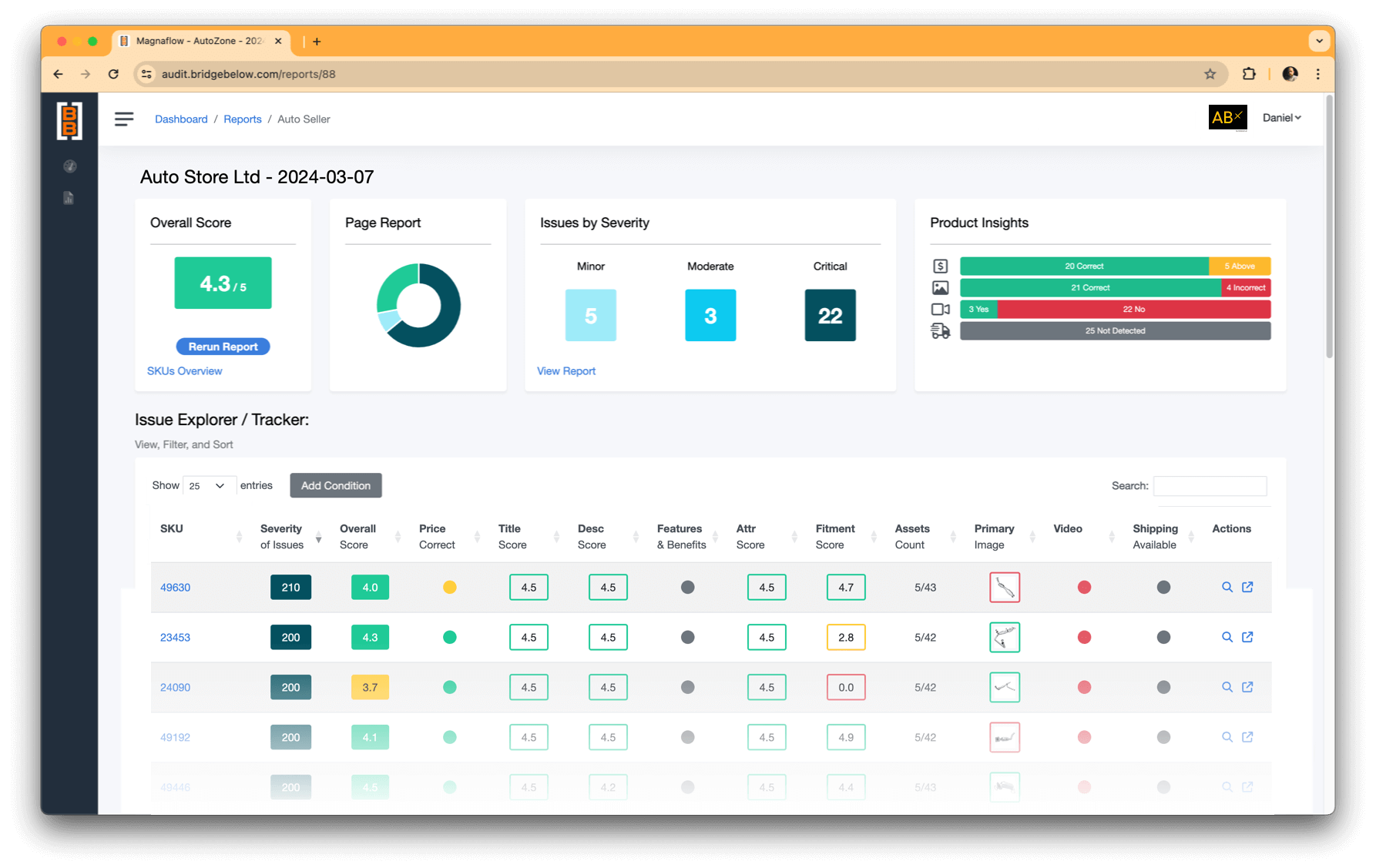

TVA automates these checks, flags issues, and provides actionable reports, helping reduce avoidable returns and improve customer satisfaction.

What can you do?

You can minimize these avoidable mistakes by identifying on-page issues and creating an actionable plan to address them using TVA.

Map reasons for returns to data on pages and audit that data

1 - Incorrect Fit or Compatibility

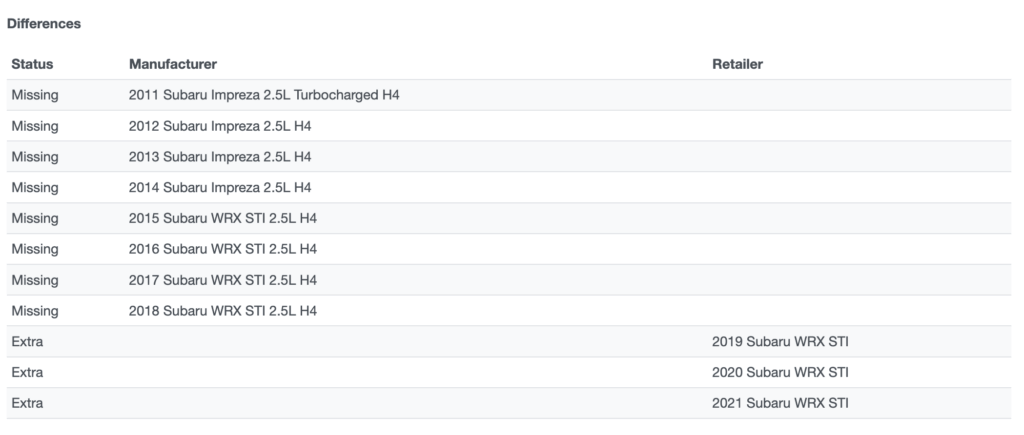

This concept is straightforward to grasp but traditionally challenging to manage. Most automotive parts pages include a section displaying fitment data, typically provided by manufacturers in standardized formats like ACES® via product management tools or feeds.

Problem: The main issue is that data integrity can be compromised in numerous ways during transfer, formatting, and updating processes. Even if accurate today, the data might become outdated or incorrect tomorrow. Continuously ensuring accuracy usually involves time-consuming manual reviews of every product against complex ACES® XML files, which diverts resources from other important areas.

Solution: TVA automates this task by scanning your site and using AI to compare your fitment data against ACES® data. It audits thousands of pages per minute and identifies discrepancies across your product range, displaying the results in an easy-to-use reporting dashboard and action planner. Incorporating TVA as a final step in your QA process to handle the repetitive task of data comparison will revolutionize your data quality and fitment data management, saving time, money, and effort.

2 - Parts Looks Different

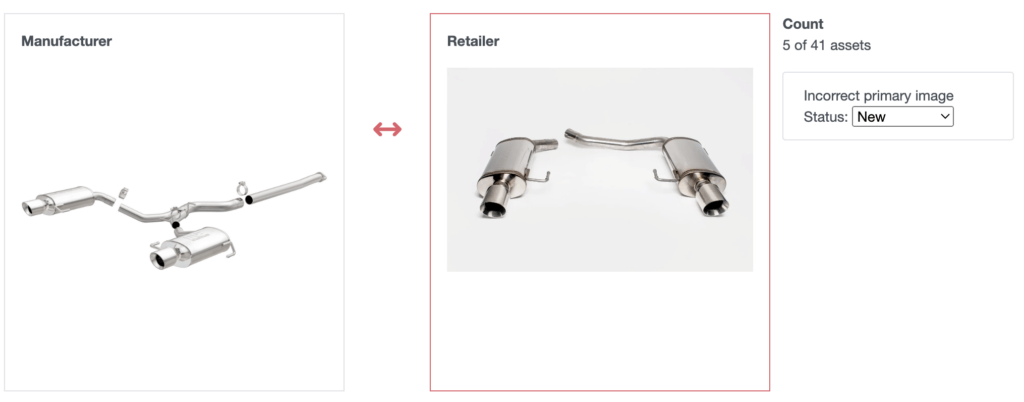

This issue is well-recognized yet challenging to resolve in auto part e-commerce due to the impracticality of manually comparing images—a task that is neither scalable nor rewarding. Incorrect images can lead to missed sales or returns, potentially incurring shipping costs.

Problem: Primary images must be consistently verified to match the latest manufacturer's PIES® data.

Solution: TVA automatically detects primary product images and compares them with those specified in the PIES® data. It flags any mismatches for review, providing a side-by-side comparison that allows your team to easily identify errors and mark them for correction. This process ensures accuracy and efficiency in maintaining image consistency across your product listings.

3 - Incorrect Materials or Attributes:

If a part is incorrectly advertised (e.g., listed as steel when it is actually aluminum), it can lead to returns. With the extensive data provided by ACES® and PIES®, it's easy to overlook or misrepresent product attributes, especially when they are critical to customers.

Problem: Checking numerous attributes one by one is impractical, yet ensuring their accuracy is crucial because details matter.

Solution: TVA automates the verification of all product attributes, helping you pinpoint areas for improvement. This tool streamlines the process of maintaining attribute accuracy, reducing the risk of errors and returns.

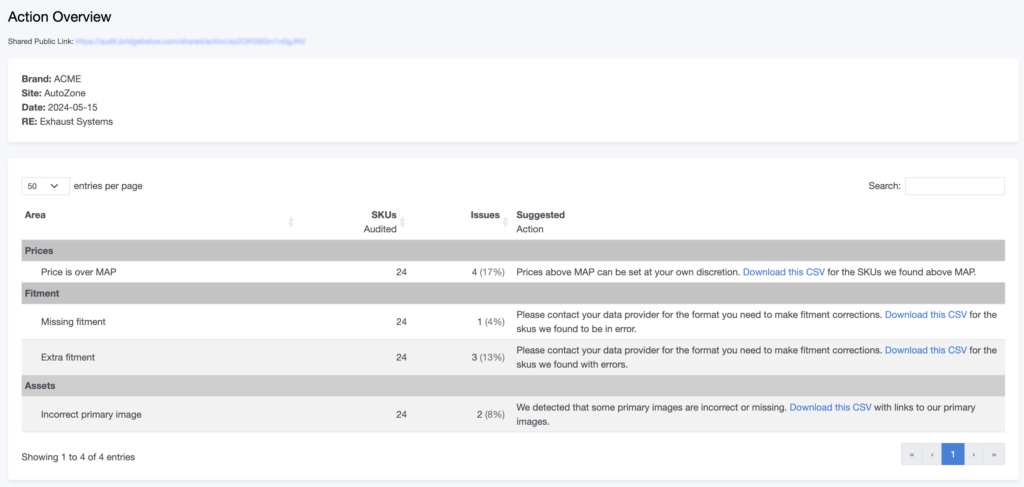

Build and share a detailed action plan

When you identify issues, mark them as requiring action. TVA will then generate a comprehensive action overview report, providing all the information your team needs to resolve the issues on-page or address them upstream at the source..

Summary

Each avoidable return impacts your sales, shipping costs, and the lifetime value of your customers. With TVA, you have the tools necessary to address three common causes of returns for online auto parts retailers. You can monitor the number of issues over time and correlate them with return rates for specific products, providing a clear view of how improvements to your pages affect your return rates.

This is just the beginning of what you can achieve with TVA. Our app offers over 100 different ways to sort, filter, and explore potential issues on your e-commerce pages, enabling you to optimize your online presence effectively.

Book a Test Drive

Experience the app live.

Our team would be pleased to discuss how TVA can help reduce your returns and enhance your operations.